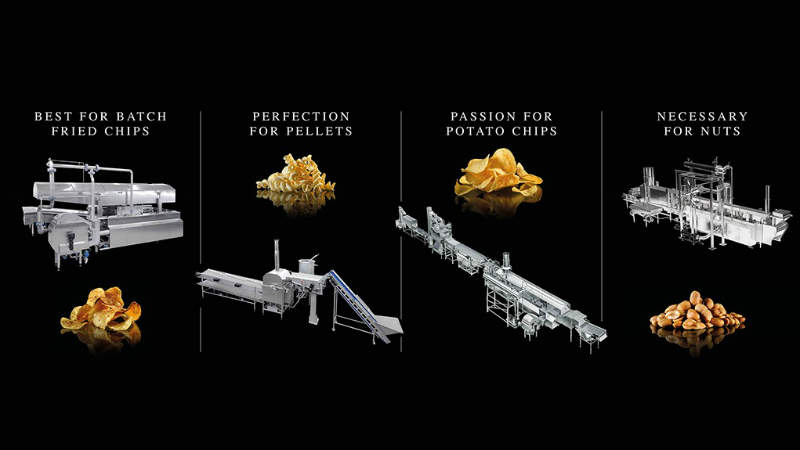

Rosenqvists Food Technologies develops and designs food processing equipment and complete lines for production of potato chips, snacks, nuts, French fries and potato specialties.

Fryers for even cooking and low oil usage

Rosenqvists’ food processing range incorporates its general concepts for frying systems, designed to add customer value:

- Accurate temperature profile control and even product flow over the full fryer width, using several internal inlets and outlets combined with temperature sensor feedback.

- Short oil turn over time, achieved by low system oil volume

- Cleansing oil from debris, with continuous full flow oil filtration

- Gentle frying oil handling, using external heating of frying oil

Frying pellet snacks, nuts, and prefabricated chips

Rosenqvists Star Wheel Fryer (SWF) can handle any raw pellet snack, from simple flat shapes to 3D products. The fryer uses the lowest amount of frying oil compared to any other fryer on the market. Capacity is dependent on the frying time, density and size of the raw pellets. The system is electrically heated.

The frying system for nuts uses Rosenqvists’ general design concepts to ensure high-quality fried nuts. The line includes a cooler, salt belt and salt dispenser.

The company used its unique know-how about oil flows, thermal design and oil filtration when designing its fryer system for prefabricated chips (stackable chips). The fryer system has been on the market for many years and is highly appreciated by Rosenqvists’ customers. The company can also supply complete lines together with its partners.

Frying potato chips

Since the first chips fryer was designed in the early 1970s by PPM AB (today known as Rosenqvists) the potato itself has always been kept in focus. Rosenqvists has designed all their machines, from potato intake to the fryer outlet, with the potato in mind.

Over the years, this approach has strengthened Rosenqvists’ knowledge and experience of the potato as raw material and how to best treat it throughout the different steps of the process from raw potato to finished product.

When designing equipment, Rosenqvists’ combines knowledge and experience with the latest computer simulation programs to design and manufacture efficient and reliable equipment for the process of producing potato chips. Rosenqvists’ general frying design concepts apply.

Frying batch style potato chips

In the Rosenqvists continuous chips fryer, it is also possible to produce what we call semi batch fried potato chips. This process uses the temperature profile of a batch fryer in a continuous fryer and will give a product with a harder bite and texture, similar to a product produced in a true batch fryer.

Frying batch potato chips

In the past, all potato chips were fried in a kettle, in batches. Over the last several years, this type of potato chip has grown in popularity and Rosenqvists’ unique batch fryer was developed to meet this market.

Rosenqvists’ process gives the potato chips a harder bite, more texture, and a darker and curlier look.

The fryer is unique and uses Rosenqvists’ general frying design concepts, but for batch frying.

Low fat potato chips

In the late 1970s, PPM AB (today Rosenqvists) developed a Defatter, which incorporated a unique process using saturated heat to remove fat, while retaining quality. This process can reduce fat content by a minimum of 10%, reducing the finished product fat content to 20%-25% from the originating 30%-35%.

Processing solutions for coated and non-coated French fries

Rosenqvists has vast experience of supplying complete processing lines for French fries.

Coated fries, wedges, and other cuts of potato products were introduced to the consumer market around 15 years ago. As one of the first suppliers, Rosenqvists developed and designed a double frying system for coated fries.

Today, the company provides full lines, including aligning shaker, batter applicator, and settling conveyor, and double frying system. Rosenqvists’ general frying design concepts apply.

Processing hash browns, rösti, croquettes, and other potato specialities

Formed potato products require special care when frying. Rosenqvists’ general design concepts provide this care, meeting the criteria´s important for production of high-quality potato specialties.

Rosenqvists’ frying system for potato specialties is suitable for frying a large variety of potato forms, including hash browns, pommes duchesses, rösti, croquettes, potato-balls and cakes.

About the company

Rosenqvists Food Technologies AB was founded in 2009 with a group of experts, all of them originating from PPM AB (Potato Processing Machinery AB), bringing their expertise in developing and designing potato process equipment.

The goal for Rosenqvists is to provide value adding solutions for the food processing industry worldwide. The company’s main focus has been potato processing but since the start of Rosenqvists in 2009, it has added several other processing areas to its portfolio.

Rosenqvists supplies complete lines for all styles of potato chips, pellets, nuts, tortillas, wet pasta, French fries, coated French fries, potato specialties and donuts.